END OF AN ERA FOR MAN AND MACHINE

Committing to one job for more than a half a century is rarely heard of these days. Yet, when you meet retired Hunter Valley Operations (HVO) Dragline Operator, Peter Constable, you soon understand why he had such dedication to his job, his machine and his colleagues. One piece of machinery which became close to Peter’s […]

END OF AN ERA FOR MAN AND MACHINE

20 November 2023

Committing to one job for more than a half a century is rarely heard of these days. Yet, when you meet retired Hunter Valley Operations (HVO) Dragline Operator, Peter Constable, you soon understand why he had such dedication to his job, his machine and his colleagues.

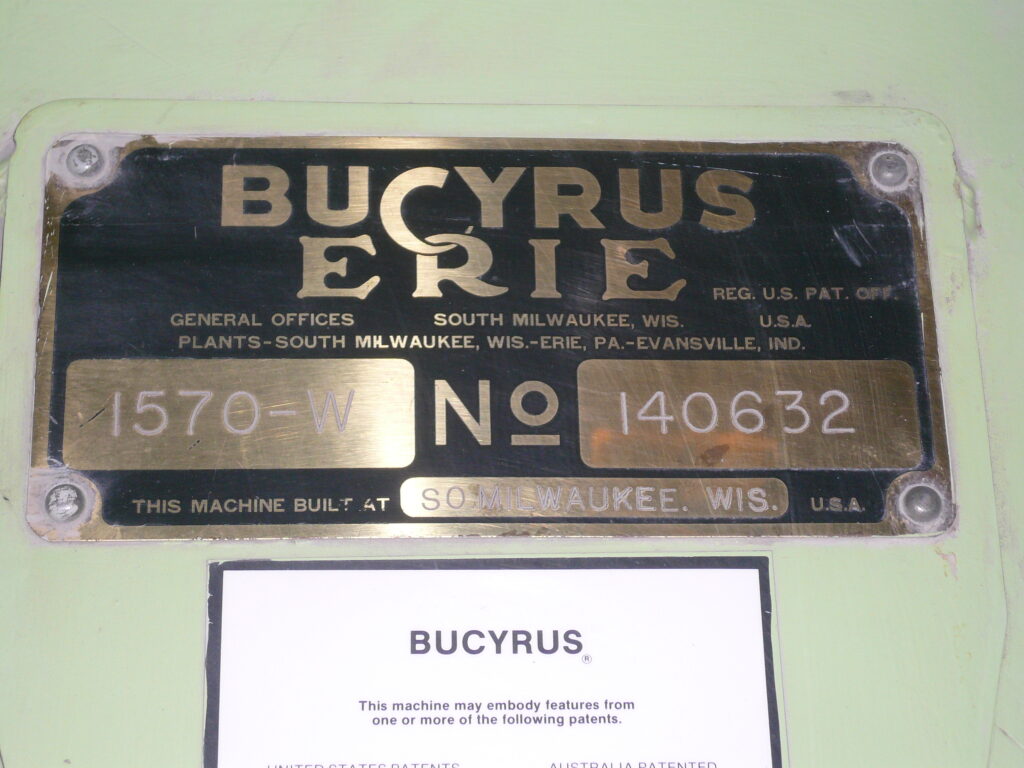

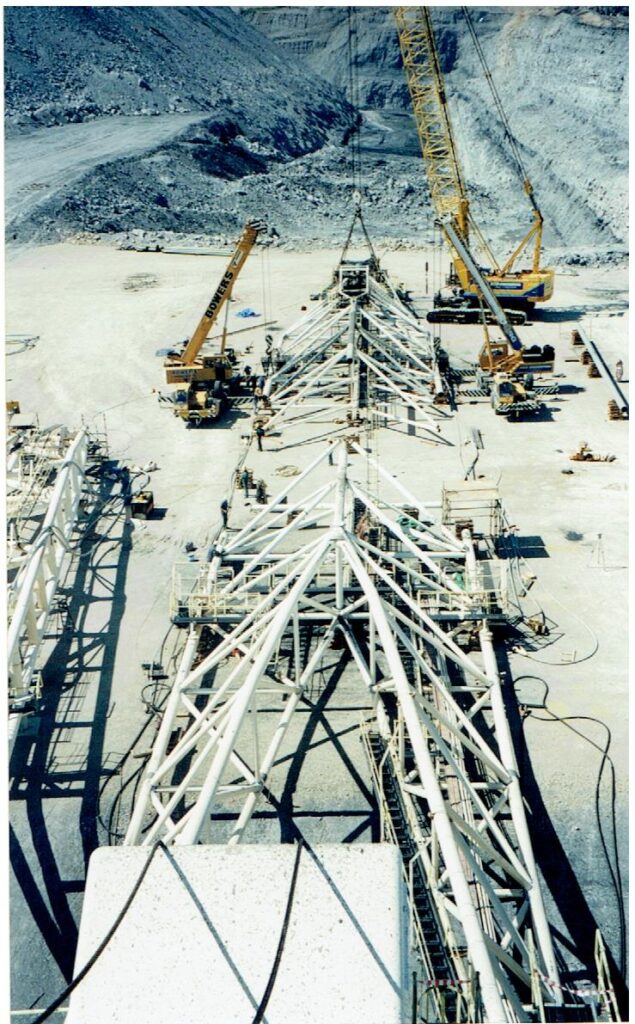

One piece of machinery which became close to Peter’s heart was Dragline 104 or ‘Big Max’ to Peter and his colleagues. This month HVO invited Peter back onsite to walk the retired 25 metre wide 3,600 tonne, 5,200 horsepower Bucyrus Erie 1570W to its final resting place.

As HVO introduces more efficient and environmentally friendly mining methods, Dragline 104 has come to the end of its operation.

With wife Lavinia by his side, Peter slid back into the operator’s seat where he had spent much of his time at HVO without missing a beat.

“I started working on the dragline in 1986, as soon it first went to work.,” Peter said.

So significant was the dragline’s introduction to HVO’s lineup of machinery, the staff thought to give it a name. Dragline 104 was to share the title synonymous with an employee battling cancer – Max Wilton.

The sheer size of Big Max stuns the uninitiated. Its boom stands tall over the pit walls like a city apartment building with a crane attached to its front. Its addition to HVO’s operations was a definitive period increasing the site’s production rates. Big Max’s capability placed it at the apex of HVO’s machine list.

“The dragline was a huge piece of machinery, able to shift 12.5 million cubic metres of material per year. It started with a 53-metre bucket, able to load 100 tonnes per trip, then a larger bucket was attached increasing the production by 10-15%.”

“When averaged out, the bigger bucket roughly saved 2,700 metres of swing per hour, equal to an average of 40,000 metres per shift in movement of the dragline’s boom over the top and bottom passes of upper and lower Liddell pit.”

Peter and his team of four on shift, consisted of one greaser, one dozer driver and two operators. Peter also trained operators throughout his whole career. So thorough was his training and tutelage, only two out of 70-odd students did not pass.

“If they had the attitude and the reflexes, they could pick it up after about six weeks. But I made them do 170 hours, and I wouldn’t sign them off as a fully-fledged operator until they had the hours.”

Peter’s choice to remain on the dragline made him know the machine better than anyone else – setting up a path to follow for other family members.

“I trained my nephew Brad. He has been on the line for the last 23 years with me.”

Peter started his career in dairy farming and construction until he saw a job advertised at HVO as a greaser. Peter applied and began one week later. The rest they say… is history.

On May 26, 1969, with a spring in his step, Peter left his new home in Muswellbrook and arrived at HVO’s Foybrook Open Cut where he built his career over the next 53 years, 1 month and 7 days.

“It’ll be sad to see Big Max shut down, but you know, there’s a lot of investment that needs to happen to keep it running. I’d love to see it keep working, but it’s a part of history now.”

Dragline 104 will be dismantled over the next year.

An end of an era at HVO, for both man and machine.